K&R Hydraulics offer a complete hydraulic oil reconditioning service.

K&R Hydraulics offer a complete hydraulic oil reconditioning service.

The condition of hydraulic oil needs to be maintained within tight tolerances. If not, it can be detrimental to the life of components within a hydraulic system. If contaminated hydraulic fluid is present, it can cause premature wear, block small control orifices, or cause inconsistent equipment operation. These, in turn, result in unnecessary expenditure inflating both maintenance costs and unplanned down time.

Common contaminants found in hydraulic oil are:

- Metal particles from worn or previously failed components,

- High water content drawn in via the breather or external source,

- External contaminants allowed to enter during maintenance or poor fluid filling practices,

- Free and dissolved gases, and

- Varnish developed in systems that operate at high load and elevated temperatures.

Hydraulic oil is expensive to both replace and dispose.

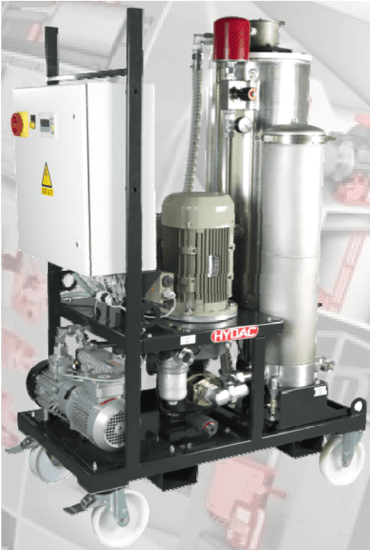

K&R have on site a Hydac FAM-45 Filtration, Dehumidifier and Degassing Unit. The unit operates on the principle of vacuum dewatering to eliminate free and dissolved water. This process also frees and dissolves gases from hydraulic and lubrication fluids.

The unit is extremely economical using HYDAC offline filter element technology with its high contamination retention capacity and filtration efficiency.

What’s more, the unit has an AquaSensor AS1000 for continuous monitoring of the water content and for controlling the unit. It’s also fitted with a particle sensor CS1000 for simultaneous monitoring of solid particle contamination.

K&R will set this up on your equipment where it can run during normal operation for fixed plant or during maintenance outages for mobile plants.

If you are experiencing issues with varnish contamination, K&R has access to a Hydac VEU (Varnish Elimination Unit) – view the video below for more about the Varnish Elimination Unit.

Should you require any additional support on the technology, achievable outcomes or pricing of this service, please do not hesitate to contact us or call us today on 02 4966 3743.